●CBN insert:

Due to their high hardness, wear resistance, thermal stability, and good chemical and physical properties, they are widely used in processing situations that require high hardness and wear resistance, especially in the processing of hardened steel, cast iron, powder metallurgy materials, and high-temperature alloys.

●PCD insert:

Due to their high hardness, high wear resistance, and long life, they perform well in the processing of non-ferrous metals and non-metallic materials and are widely used in the automotive, aerospace, electronics, and other industries.

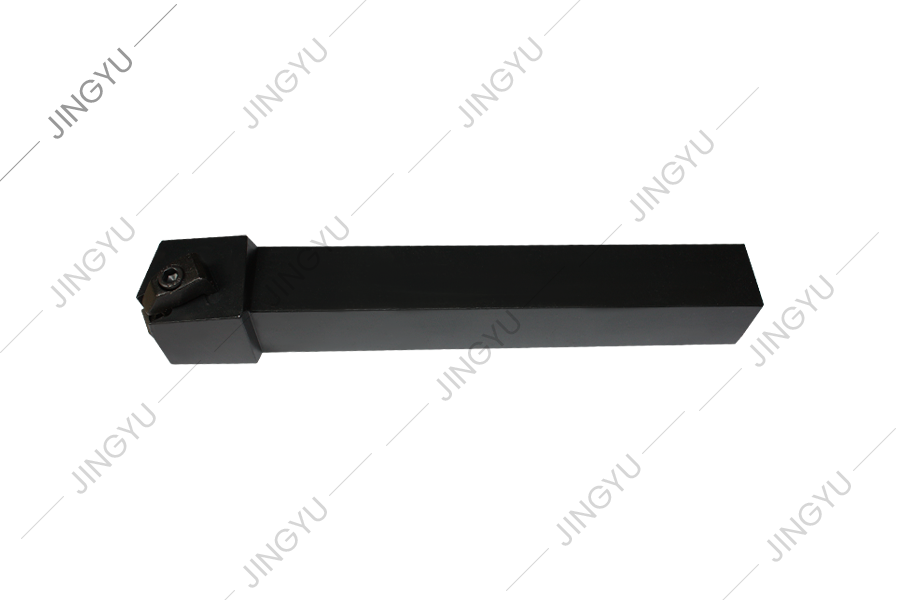

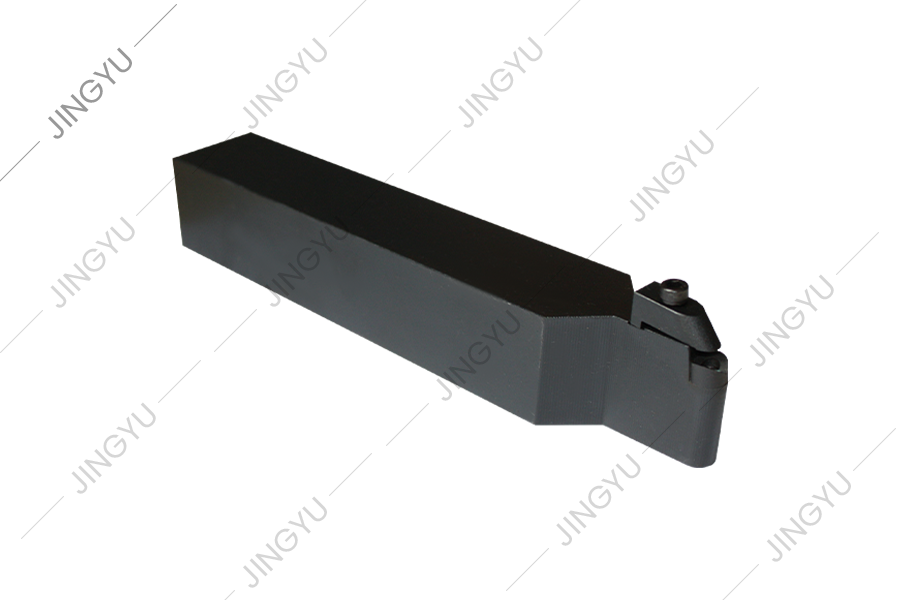

●Turning tool holder:

Due to their high precision, stability, durability, and easy replacement and adjustment, they play an important role in various turning processes and are an effective tool for improving production efficiency and reducing costs.

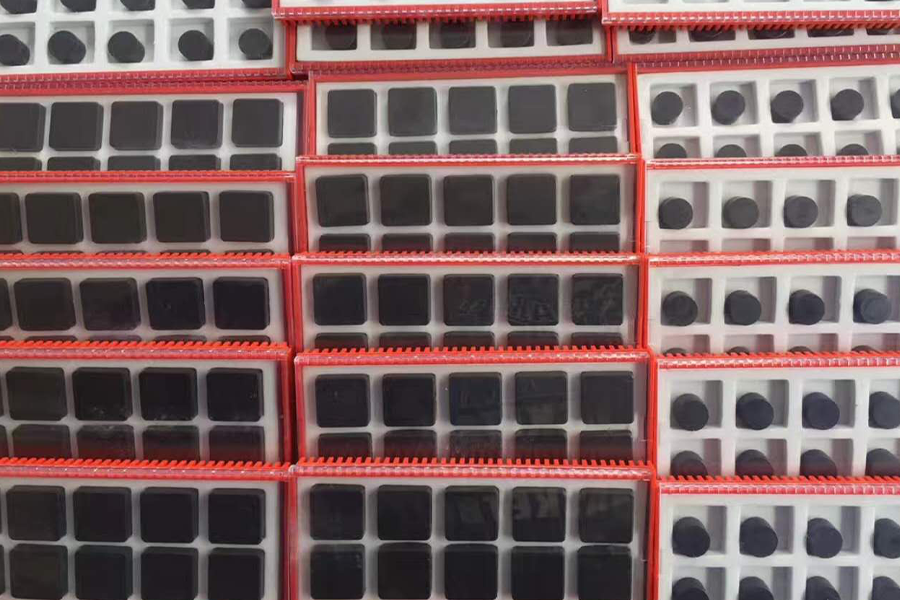

Lathe Spare Parts

This series mainly provides common-wearing parts for CNC roll lathes, such as CBN blades, PCD blades, chucks, screws, etc.

Get A Quote

About Us

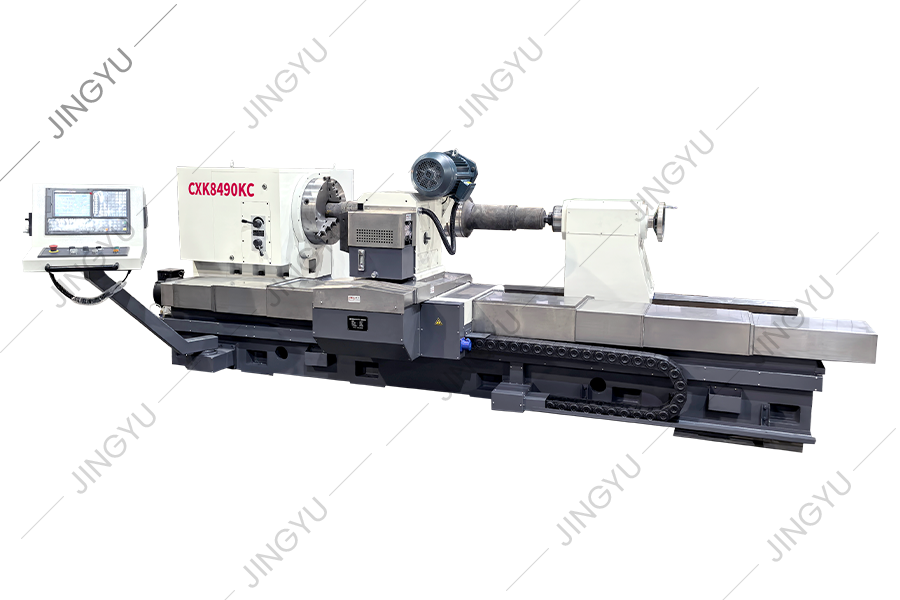

Nantong Jingyu Machinery Co., Ltd.

Founded in 2000, we are an enterprise specializing in the development, production and sales of CNC machine tools, special machine tools and supporting automation products.As a China Lathe Spare Parts Manufacturers and Lathe Spare Parts Suppliers, our company has self-operated import and export rights and has passed ISO9001/2015 quality certification. And has a number of independent intellectual property rights.

News

-

Introduction to CNC Roll Milling Machines CNC (Computer Numerical Control) roll milling machines are...

READ MORE -

The Role of Automatic Lubrication in CNC Milling Machines An automatic lubrication system in a CNC m...

READ MORE -

Overview of Automatic Measuring and Online Inspection in CNC Roller Ring Lathes A CNC roller ring la...

READ MORE -

Introduction CNC roll milling machines are essential in the manufacturing industry for processing me...

READ MORE -

From November 11th to 14th, 2025, the 31st Russian International Metallurgy, Casting, and Steel Indu...

READ MORE

English

English русский

русский عربى

عربى